Just how much visual inspection data is worth.

Inspection data has tremendous worth, now and in the future.

by Ditte R. Lønstrup

Inspection data has tremendous worth, now and in the future.

For Power-line inspections, it can be easy to look for a one-and-done solution, but when it comes to pole-maintenance, is it worth it?

In most cases, utilities are missing out on huge benefits, by not using their inspection data properly. The excuse will, more often than not, be budgetary constraints.

But too few consider how do power outages impact their revenue and customer satisfaction? And what about your business customers? What are their losses if your power network goes down?

The risk of neglecting an ongoing inspection program heavily outweighs the benefits. By maintaining a consistent inspection cycle and proactive maintenance, these power failures can be reduced substantially, leaving your utility’s bottom line looking a lot better.

This article investigates the short- and long-term advantages of using drones for inspections, coupled with Data Management software for analysis and storage.

We consider short term benefits immediate; the benefits that you will see during the inspection and analysis.

These benefits mostly come from the usage of drones in inspections, compared to manually completed inspections, which is often the previous method.

The following numbers are from a proof of concept project in a large utility.

Using drones and Data Management software for inspections, as opposed to traditional methods:

– A minimum saving of $2 per distribution pole inspected and analysed.

– Savings increased with number of poles, up to $10 per pole.

– Data acquisition speed was improved by 40% using a pilot and drone compared to a lineman.

Numbers are from a recent experiment Scopito conducted in collaboration with a Virginia-based co-op.

Data that is analysed and stored on a secure server, can always be revisited to determine where mistakes were made, and revised if needed.

With Scopito, detected faults are easily dispensed to work order tickets for the maintenance team. This improves workflow reliability, and the quality of fault information that repair-crews have available.

As one of the Drone Service Providers using Scopito, told us recently:

The GIS information is really a game-changer for coops.

Humans are visual; when we can see a satellite image of the line, see a structure on the ground, we begin to visualize where we are spatially. That makes it a whole lot simpler to look at images and data from an inspection, and really understand it.

Another DSP client of Scopito was told the following when he flew an inspection job for an American coop:

”I want a paper report. I want to see the issues, where they are and what they are. I want it to be properly annotated and know the GPS-coordinates.

I know this is probably impossible for you to do.”

– The coop client

“Nah, not really.” was Curtis’ response, as he pulled up his Scopito report.

Long-term benefits are considered those seen within the first year of regularly scheduled inspections and maintenance. Their value grows as the amount of inspections increases.

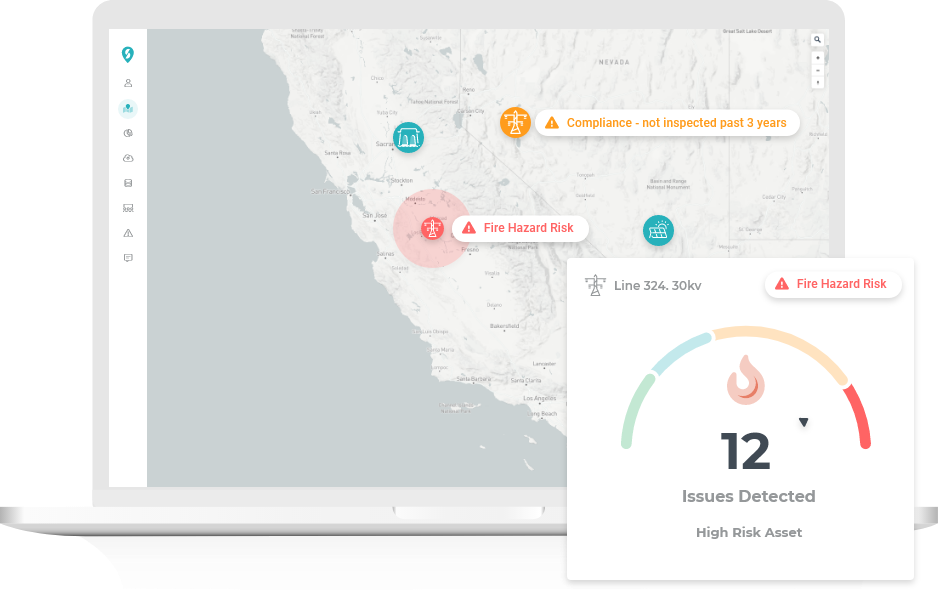

Once you start collecting data regularly, your Utility will be able to use it for predictive maintenance and risk mitigation.

Once you start inspecting regularly, you can increase the level of detail, with which you analyse the data, moving towards a predictive- and eventually preventive maintenance focus.

This is where we start working with preventive maintenance and really seeing results skyrocketing.

Keeping inspection data in Scopito, allows you to start seeing trends over time. You can use these trends to discover more about your operations, the obstacles, and the opportunities.

Another advantage to maintaining a consistent inspection program is asset management. Scopito can implement artificial intelligence that will identify the components of your powerline network and produce a highly detailed and accurate inventory report. And, right from the same inspection imagery. No need to conduct a separate operation.

This allows the Power Utility to manage hardware lifecycles by creating scheduled retire and refresh for aging equipment. Again, automating these processes minimizes the need for complex manual processes for managing your Lifecycle Program and thus, improving the technology and efficiencies of your powerline network.

The added advantage of having better inspection data is that repairs become much cheaper.

Being able to effectively identify a faulty part, means you can replace that exact part, whereas you might earlier have had to replace an entire section of the asset.

Early detection of eroding parts, makes adding to the assets lifetime highly realistic.

Visual inspection data is worth thousands of hours and millions of dollars to cooperatives, that are willing to invest in it. Are you?

So in conclusion, we ask, just how much visual inspection data is worth?

In today’s marketplace, no matter the industry, data is everything, and perhaps the real value of the data can be calculated by the cost of power outages to your customers, or the extreme costs of emergency repairs.

More content from us

Enter your details below to continue

First and last name is missing.

Company name is missing.

Phone number is missing.

Email is missing

I have read the Terms of Use and declare that I agree

Missing accept for our Terms of Use

Please send me occasional e-mails about the product.

14 Days free trial starts automatically when you sign up